Tech

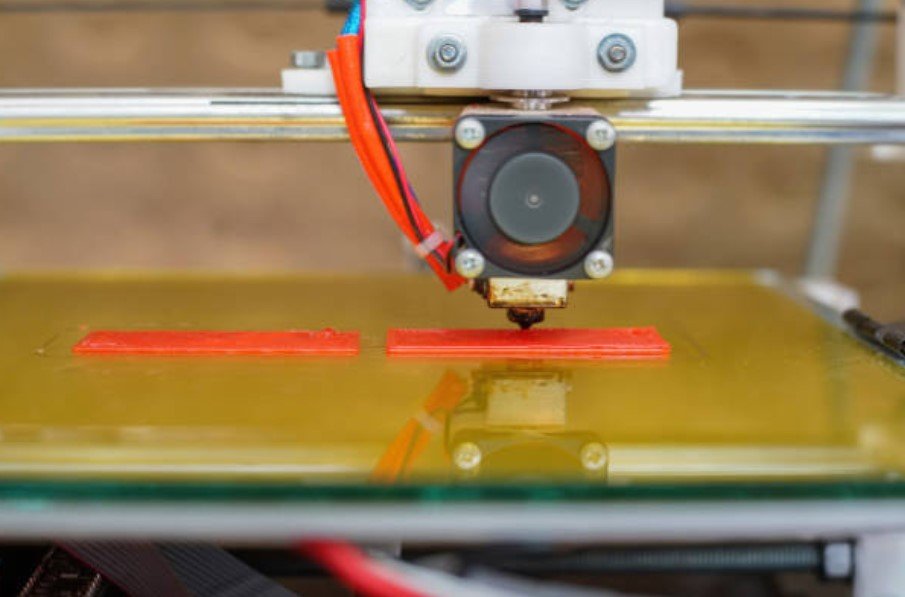

How to Properly Clean and Maintain Your 3D Printer After Using ASA Filament

ASA (Acrylonitrile Styrene Acrylate) filament is renowned for its UV resistance, mechanical strength, and excellent weatherability, making it a top choice for outdoor applications and functional prototypes. However, like any specialised material, ASA requires specific care when it comes to cleaning and maintaining your 3D printer. By following these guidelines for nozzle cleaning, bed maintenance, and clog prevention, you can ensure that your printer remains in optimal condition and produces high-quality prints consistently.

Nozzle Cleaning: Keep Your Prints Crisp and Clear

Quality ASA 3D printing filament has a higher melting point than standard filaments like PLA, which means it can sometimes leave residue in the nozzle, leading to clogs or poor extrusion quality. Proper nozzle cleaning is essential to avoid these issues.

- Perform a Cold Pull: After printing with ASA, perform a cold pull using a cleaning filament or a high-temperature material like nylon. Heat the nozzle to around 250°C, insert the cleaning filament, and then let it cool to about 150°C before pulling it out. This process will remove any lingering ASA residue and prevent buildup.

- Use a Brass Wire Brush: For more stubborn deposits, gently brush the nozzle with a brass wire brush while it’s heated. This helps dislodge any carbonised material that could obstruct the nozzle.

- Nozzle Replacement: If you notice that your nozzle is consistently clogging or if print quality deteriorates over time, consider replacing the nozzle. Regular nozzle maintenance ensures smooth filament flow and maintains the precision of your prints.

Bed Maintenance: Ensure Adhesion Without Damage

Proper bed adhesion is crucial when printing with ASA filament, as it can warp if not securely fastened to the print bed. However, maintaining your bed after printing is equally important to prevent damage and ensure longevity.

- Clean the Print Surface: After each print, remove any remaining ASA residue from the bed using isopropyl alcohol and a lint-free cloth. This will keep the surface clean and ready for the next print, reducing the risk of adhesion issues.

- Use the Right Adhesive: If you used an adhesive like glue stick, hairspray, or a specialised bed adhesive for better ASA adhesion, ensure that you clean it off thoroughly after each print. Over time, built-up adhesive can create an uneven print surface, leading to warping or bed leveling issues.

- Inspect the Bed for Damage: ASA prints at higher temperatures, which can sometimes lead to damage or wear on the print bed. Regularly inspect your print surface for scratches, dents, or other damage that might affect adhesion or print quality. Replace the print surface if necessary to maintain a consistent printing environment.

Preventing Clogs: Keep Your Printer Running Smoothly

Clogs can be a significant issue when printing with high-temperature materials like ASA, but they are preventable with proper care and maintenance.

- Store Filament Properly: ASA is slightly hygroscopic, meaning it can absorb moisture from the air, leading to filament degradation and nozzle clogs. Store your ASA filament in a cool, dry place, preferably in a sealed container with desiccant packs, to maintain its quality.

- Regularly Purge the Nozzle: After each print, or if you’re switching between different filament types, purge the nozzle with a small amount of ASA or cleaning filament. This helps clear any remnants from the previous print and reduces the risk of clogs.

- Temperature Control: Make sure you are printing at the correct temperature for ASA filament, typically between 240°C and 260°C. Printing at too low a temperature can cause partial melting, leading to clogs, while too high a temperature can cause filament degradation inside the nozzle.

By following these simple yet effective maintenance practices, you can keep your 3D printer in top condition, even when working with demanding materials like ASA filament

Regular nozzle cleaning, diligent bed maintenance, and preventive measures against clogs will ensure your prints are always of the highest quality. By taking these steps, you can enjoy smooth, successful prints and extend the lifespan of your 3D printer, ensuring it remains a reliable tool for all your creative projects.

-

Entertainment4 weeks ago

Entertainment4 weeks ago123Movies Alternatives: 13 Best Streaming Sites in 2026

-

Entertainment1 month ago

Entertainment1 month ago13 Free FMovies Alternatives to Watch Movies Online in 2026

-

Entertainment1 month ago

Entertainment1 month ago13 Flixtor Alternatives to Stream Free Movies [2026]

-

Entertainment1 month ago

Entertainment1 month agoGoMovies is Down? Here are the 11 Best Alternatives