Food

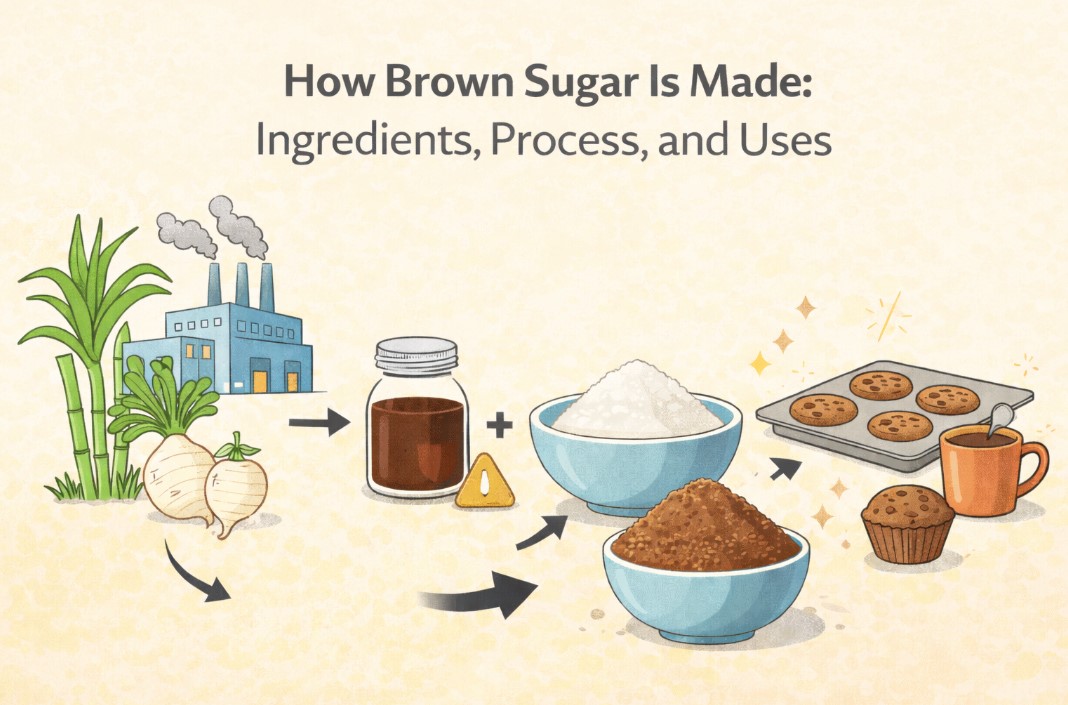

How Brown Sugar is Made: Ingredients, Process, and Uses

Brown sugar is a common kitchen ingredient used in baking, cooking, and beverages. Many people use it regularly without knowing how it is produced or why it differs from white sugar. Understanding how brown sugar is made helps explain its color, texture, flavor, and best uses. This article explains the ingredients involved, the production process, and how brown sugar is commonly used, using clear and simple language.

What Brown Sugar is

Brown sugar is a type of sugar that contains molasses, which gives it a brown color and moist texture. It is not a raw or unprocessed sugar in most modern food systems. Instead, it is usually refined sugar that has molasses added back into it after processing. The amount of molasses determines how dark the sugar is and how strong its flavor will be.

There are generally two common varieties: light brown sugar and dark brown sugar. Light brown sugar contains less molasses and has a mild flavor, while dark brown sugar contains more molasses and has a stronger taste.

Main Ingredients Used

The ingredients used to make brown sugar are simple and limited. The primary components include:

- Sugarcane or sugar beet as the raw source

- Molasses derived during sugar processing

In most commercial production, white sugar is first created and then combined with molasses. This method allows producers to control moisture level, color, and flavor more accurately.

The Role of Sugarcane and Sugar Beets

Brown sugar begins with sugarcane or sugar beets. Sugarcane is a tall tropical plant, while sugar beets are grown in cooler climates. Both contain sucrose, which is the base form of sugar.

The plant material is harvested and transported to processing facilities, where it is cleaned and prepared for extraction. Although both sources can be used, sugarcane is more commonly associated with brown sugar production due to flavor preferences.

Extracting Sugar Juice

The first step in production is extracting juice from the plant. Sugarcane is crushed to release its juice, while sugar beets are sliced and soaked in hot water. The resulting liquid contains sucrose along with impurities like plant fibers and minerals.

This raw juice is filtered to remove solid material. The remaining liquid is then heated to evaporate water and concentrate the sugar content.

Crystallization Process

After the juice is concentrated, it is boiled under controlled conditions. As water evaporates, sugar crystals begin to form. At this stage, molasses separates naturally from the crystals.

The mixture is spun in centrifuges to separate the sugar crystals from the molasses. This process creates raw sugar crystals and liquid molasses as two separate outputs.

Refining into White Sugar

To produce white sugar, raw sugar crystals go through further refining. This includes washing, dissolving, filtering, and re-crystallizing the sugar to remove remaining impurities and color.

At the end of this stage, the result is pure white sugar with no molasses content. This refined sugar becomes the base material for many sugar products, including brown sugar.

Making Brown Sugar from White Sugar

Most brown sugar sold today is made by adding molasses back into refined white sugar. This controlled blending ensures consistent quality and texture. The molasses coats the sugar crystals evenly, giving brown sugar its soft and moist characteristics.

Light brown sugar contains a smaller percentage of molasses, while dark brown sugar contains a higher percentage. The blending process is carefully measured to achieve the desired result.

Traditional Methods of Production

In some regions, brown sugar is produced without fully refining it into white sugar first. In these traditional methods, sugar crystals are left with some natural molasses intact. This type of brown sugar may have a coarser texture and less uniform color.

However, this approach is less common in large-scale commercial production because it is harder to standardize.

Texture and Moisture Content

One of the defining features of brown sugar is its moisture. Molasses is hygroscopic, meaning it attracts and holds moisture. This is why brown sugar tends to clump and harden when exposed to air.

Proper storage in an airtight container helps maintain its softness. If brown sugar hardens, moisture can often be restored with simple methods such as sealing it with a damp object.

Flavor Characteristics

Brown sugar has a deeper flavor than white sugar due to the presence of molasses. The flavor includes notes of caramel and mild bitterness, which makes it suitable for baked goods and sauces.

Dark brown sugar provides a stronger taste, making it ideal for recipes that need richness, while light brown sugar works well in lighter baked items.

Common Uses in Cooking and Baking

Brown sugar is widely used in both sweet and savory recipes. Its moisture and flavor contribute to texture and taste.

Common uses include:

- Baking cookies, cakes, and muffins

- Sweetening sauces and glazes

- Enhancing flavor in marinades

- Adding depth to beverages

- Topping oatmeal and cereals

Its ability to retain moisture helps baked goods stay soft longer.

Differences Between Brown Sugar and White Sugar

Brown sugar and white sugar differ in more than color. Brown sugar contains slightly more minerals due to molasses, but nutritionally they are very similar. The main differences lie in flavor, moisture, and cooking behavior.

In baking, brown sugar can affect texture, spread, and browning. Recipes often specify which type to use for a reason.

Storage and Shelf Life

Brown sugar can last a long time if stored properly. Exposure to air causes moisture loss, leading to hardening. Keeping it sealed tightly prevents this issue.

If brown sugar becomes hard, it is still safe to use once moisture is restored. Proper storage reduces waste and maintains quality.

Health Considerations

Brown sugar is sometimes believed to be healthier than white sugar, but the difference is minimal. The molasses adds trace minerals, but not enough to make a significant nutritional impact.

Moderation is important when consuming any type of sugar. Brown sugar should be treated as a flavoring ingredient rather than a health product.

Final Thoughts

Understanding how brown sugar is made provides insight into why it behaves the way it does in recipes. From its simple ingredients to its carefully controlled production process, brown sugar is a refined product designed for consistency and flavor.

Knowing how it is produced helps home cooks and bakers choose the right type for their needs. Whether used for baking, cooking, or sweetening, brown sugar remains a versatile and widely used ingredient in kitchens around the world.

-

Entertainment1 month ago

Entertainment1 month ago123Movies Alternatives: 13 Best Streaming Sites in 2026

-

Entertainment2 months ago

Entertainment2 months ago13 Free FMovies Alternatives to Watch Movies Online in 2026

-

Entertainment1 month ago

Entertainment1 month ago13 Flixtor Alternatives to Stream Free Movies [2026]

-

Entertainment1 month ago

Entertainment1 month agoGoMovies is Down? Here are the 11 Best Alternatives